SURFACE PROTECTION SERVICES

SURFACE PROTECTION

Gulf Classic International Oilfield Services Limited has extensive knowledge and practical experience in the various techniques available for surface preparation and associated protective surface preparation and protective coating application methods to meet required industry quality standards.

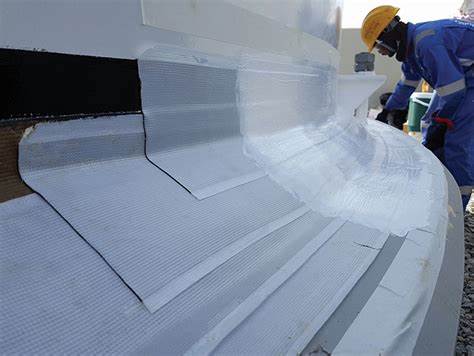

We own an extensive inventory of equipment including semi-automated propriety systems enabling us to undertake surface preparation by means of UHP water jetting (Hydro-blasting), abrasive (wet and dry) blasting and mechanical methods including dust-free and recyclable options. Once prepared, we can apply a range of coating and composites including industrial epoxies, alkyds and urethanes, non-slip helideck and coatings, screeds and tiles, tank and vessel linings and anti-fouling coatings by means of conventional spray, airless spray or manual brush roller application as appropriate. Integrity.

Our core in-house capabilities and project management skills give us the ability to provide integrated solutions and to deliver turnkey painting programs for our clients as they combat corrosion and maintain their assets integrity.

Offshore Sureface Protection

Reliability of our surface protection products, performance and services is key to all aspects of our operations. We are confident that we have the specialist technical skills, resources and capabilities to excel in service delivery.

Our capability includes surface protection, passing fire protection, composite wraps and repair technology, technical support, pre-survey work and cost containment.

We have the resource capability to mobilise qualified supervision and inspectors. Our highly skilled labour force consist of leading experts in their fields and are fully conversant in dry and wet blasting offshore techniques and painting offshore also.

Tank Coating

You can use the best coating/paint products in the world, but if the surface is not prepared properly before the application, premature failure of the coating and deterioration of the substrate metal is inevitable. Our tank Coating Specialists study each project and determine the optimum approach to surface preparation based on site specific conditions such as tank materials, existing corrosion, humidity and other environmental conditions.